Holes In The Floor

Updated:

During my summer trip, I pulled in at Burtdad autos for the once over and found a few things that didn't look entirely tickety-boo. Specifically, there were a few areas of rust on the floor that looked a little more serious than I'd given them credit for. On closer inspection (by which, I mean, after beating the crap out of them with a hammer), I discovered the metal had already given up in some places.

The first area that needed attention was beneath the pedals. Twenty years of fancy footwork had worn the area to dust, leaving visible holes that penetrated the floor mat and the steel floor beneath. We'll get to that in a minute; since I only took a few shots, it'll make more sense to start with the second problem.

The left side of my cabin floor was already well into the "giving up" part of the Transit life cycle, and this is a huge problem, since it's the area where the wheel arch meets the floor and the area that takes the weight of the passenger bench. It was going to need serious welding.

* At this point, my welding level was: Can weld "Burt" into plate steel (see ![]() Adventures At 5000 Degrees).

Adventures At 5000 Degrees).

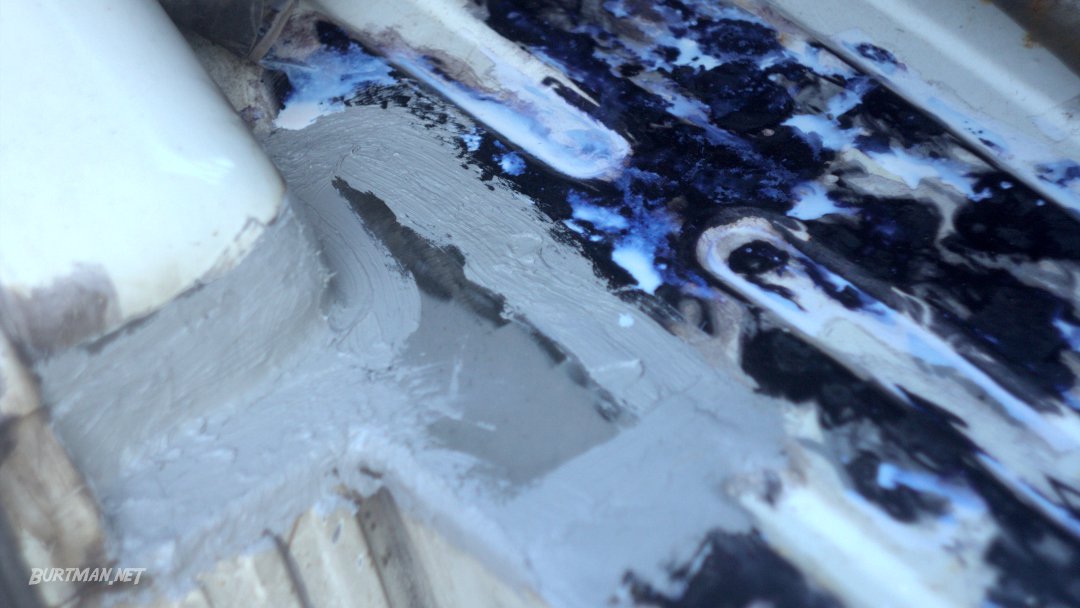

Grinding the rust away, to find where the metal still had strength, revealed the true size of the problem.

Yikes.

Beneath all that rust and decay, there would be some solid metal, and the fist job would be to clean it up, so I could weld onto it.

Cutting away the rotten metal left me with this:

Once I'd identified the actual area that needed work, I found a sheet of steel and set about making a cover. I just measured and drew roughly, cut out with the angle grinder, and tacked it over the top of the damaged area with the MIG welder.

Once the new sheet metal was welded in position, I ground the edges flush with the step, hammed them down and began recalling my two hours of YouTube training, before setting about melting the sheet steel into the van in a very permanent way. After that, and no severe damage or total write-off to report, a coating of seam seal, to prevent water coming back in at a later time and rusting up the place. And the blue fluid is to treat the exposed metal against rust, too.

* At this point, my welding level seems to have elevated to the nationally acceptable "It appears to be solid and nothing is on fire" standard.

Now, as I mentioned, this was actually the second job. I showed this one first, as I only took photos of the first job's "finished" state, and wanted to show them next.

So, here's the area below the pedals...

Since all of these problems were on the floor, which will always be covered by the floor mat, I wasn't too interested in perfectly fitted steel inserts, expertly welded and blended with the original metal. Basic treatment and overlay metal was good enough for me. Besides, I haven't the skill for that, yet.

This area also just has a steel plate welded over the top of the hole, after grinding and treating the area to make sure the underlying rust would not return [any time soon]. With this lot done, a couple of layers of primer and paint, and a temporary driving seat (just for moving the van to the "drying area").

The floor mat goes back in, followed by the seats, and I'm a happy lad, again, and so is Burt.

After completing three such repairs (I also repaired a rotten step sill, but didn't photograph it), my new welding level has reached the internationally recognized "not horrendous*" automotive standard. Yippee.

* With "horrendous" being defined as dangerous or generally useless or of horrific quality.

So that's what I get up to when I'm on vacation.

Sign In To Leave A Comment

There are no comments marked as public for this item.

Stay Up To Date

Diving Deeper

Diving Deeper Read around 900 times

Read around 900 times For Everyone

For Everyone