Replace Control Arm Bushing

Updated:

This is a big job, and it requires level ground, good weather, specialist tools and time. If you don't have all four, you shouldn't begin, or you could end up rendering your van unusable and unsafe to occupy.

Investigation

Over the last week or so, there's been a loud knocking sound coming from the front of the van when braking firmly, cornering and traversing speed bumps. It's not a creaking, it's not a continuous sound and it's not subtle. It sounds like someone thumping the sub frame with a lump hammer. That would be something that qualifies for an urgent investigation.

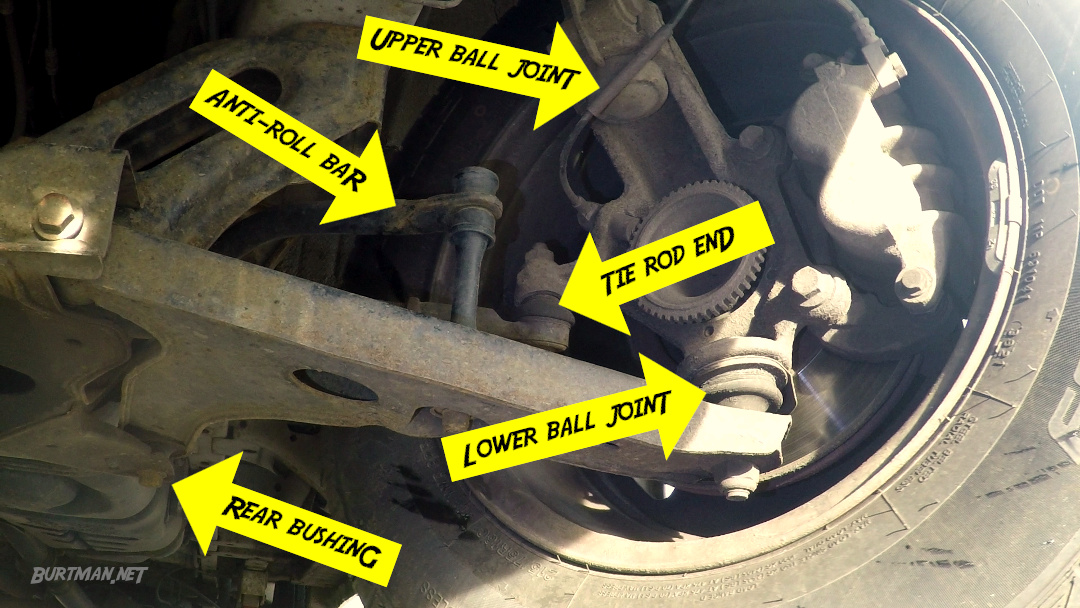

At first, I suspected that one of the ball joints may be on the way out, but there are several suspects, so a few checks were necessary.

This week's line-up.

The first check is the easiest; you just bounce the suspension on either side and listen for knocks. While you do this, you feel how smooth the suspension is. If knocking is heard while bouncing the suspension, the problem will be in one of the vertically-aligned joints or the suspension strut. This was not the case for me. On to the next test.

Jack the van up at the lower control arm, until the wheel is off the ground, then try to wobble the wheel from top to bottom and from side to side. If there's any play, or you hear knocking, then the problem will be in a ball joint or laterally-aligned steering component. There was no play in either wheel, so I then jacked the whole front end up at the sub frame and tried turning the steering wheel rapidly (with engine running) to check for play in the steering system. If the knocking was heard during this test, it would be coming from the steering column, tie rods, or even power steering gearbox. This was not it, either.

However, I had a nice clue when lifting the van; the exact knocking sound I'd been hearing during operation occurred once as I lifted the van, and it came from the sub frame bolt at the back end of the control arm. This gave me a place to look and a good idea what I'd find when I did.

As it turned out, the knocking was only caused by the sub frame bolt being loose, which meant that the subframe could actually slightly move up and down. The cure was just to tighten the living hell out of it with a long breaker bar (those 21mm bolts can take far more pressure than most people can exert, so it doesn't necessarily require the

Torque Wrench (although I obviously recommend using it at the correct setting)).

Torque Wrench (although I obviously recommend using it at the correct setting)).

But...

We know scissor jacks are the last resort, but mine is tall enough to lift the van at the sub frame, which my bottle jack is not.

Since I had lifted the van this far, I decided to have a look around, and found that the rear bushings on both sides had perished and will need to be replaced. I ordered the full set of replacement parts from eBay and set them aside for when I could be bothered to actually take on such a job. That time is nigh; I can feel it.

Incidentally, the torque value for sub frame bolts in my manual is extremely low. I almost broke a thick steel pipe, when I was trying to get them out (in order to replace the clutch), but the manual claims that 113 ft-lb is sufficient. It's not. I've seen a few other online discussions on this issue, with various different cars and trucks, and the overwhelming majority conclude that cranking those bad boys as tight as you possibly can and then some is the way to go. Accordingly, I wound mine up to 180 ft-lb, only because they'd be coming off again, once the new bushes arrived, but they'll be going up a lot tighter than that, when they do finally go back on. I can't possibly tell you to overrule your vehicle manual, but I can tell you that 21mm bolts can take a lot more than the 60-90 ft-lb suggestions I've seen over at the Mustang discussion, and given that there are only two of them on each side, and that they take the weight of most of the engine and drive train... well, you get the point.

FYI: Some vans require replacement of the whole arm, which will usually include the lower ball joint and a new set of tie rods. On other vans, just the bushes may be replaceable (as on mine). This is something you'll need to check out before buying parts. In any case, the process will be almost identical (except for the bushing replacement steps), as the entire assembly will need to be removed, regardless of which part(s) you will replace.

Stay tuned (a little longer).

Public Comments

Posted by TerezaK_100 on

September 23 2024, 03:14 pm.

Stay Up To Date

Diving Deeper

Diving Deeper Read around 2,700 times

Read around 2,700 times For Everyone

For Everyone

Looks dangerous. Hope you get it sorted soon.